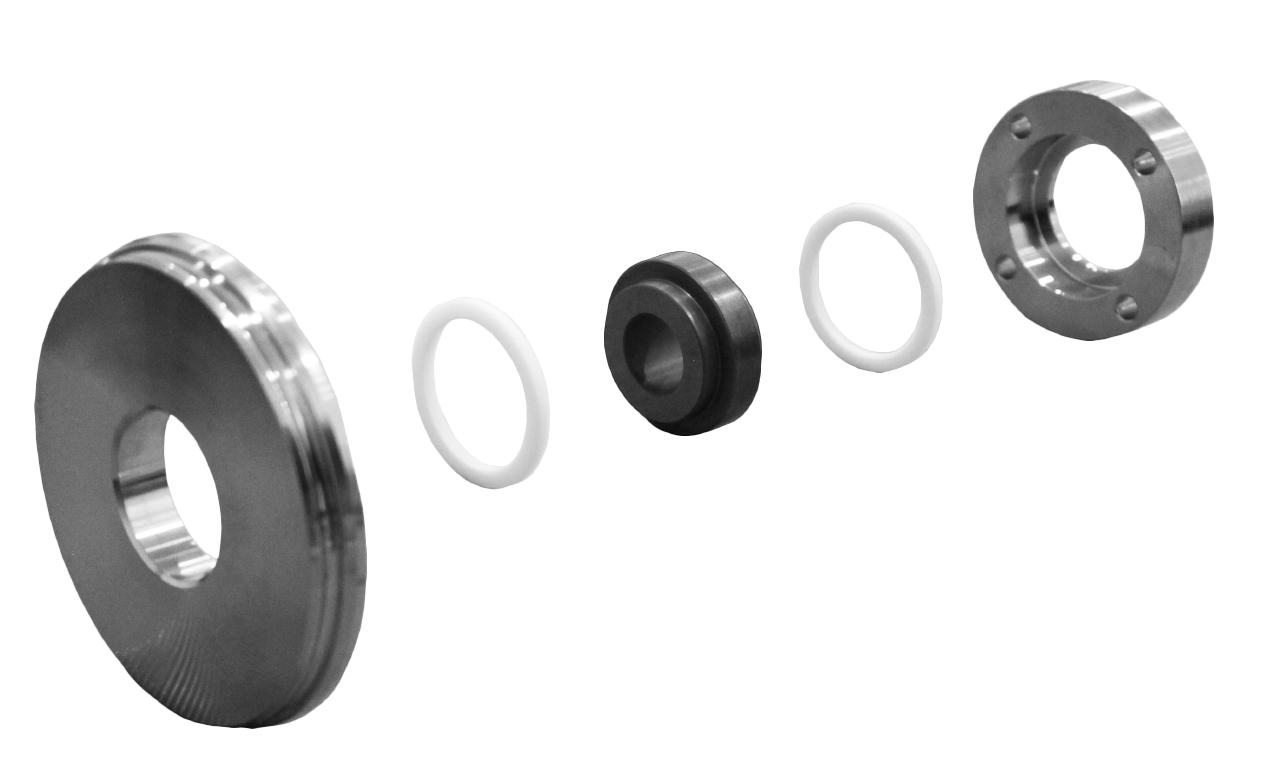

Spare faces for mechanical seals

Spare faces for mechanical seals are replacement parts for worn or damaged seal faces in mechanical seals. They are typically made from materials such as carbon, ceramic, or tungsten carbide, and are designed to provide a high level of durability and wear resistance.The choice of material for the spare face will depend on the specific application, with factors such as the operating conditions, the type of fluid being sealed, and the speed and pressure of the equipment all taken into consideration. Spare faces can be easily installed by trained technicians, helping to extend the lifespan of mechanical seals and reduce downtime in critical machinery.

Spare faces for mechanical seals are important for several reasons. Mechanical seals typically consist of three sealing points, and the primary seal is a spring-loaded bearing with two flat faces that run against each other. These faces are susceptible to wear and damage due to the frictional forces involved in their operation. Spare faces can be used to replace worn or damaged faces, extending the lifespan of the mechanical seal and avoiding costly downtime. Ceramics are an effective material for seal faces due to their excellent wear characteristics, chemical inertness, and compatibility with a wide range of fluids. Proper installation and cautious handling of spare faces can help prevent wear and damage, but it is important to note that ceramic faces can shatter if dropped on concrete and cannot handle thermal shocks.